|

|

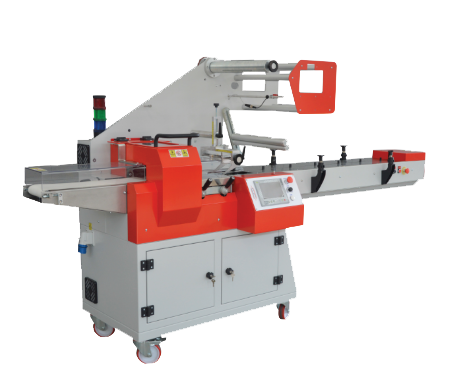

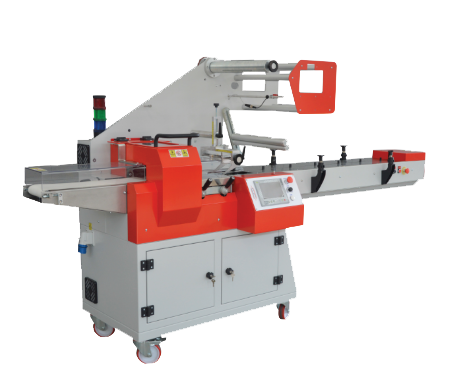

flowpack packaging machinesA flowpack packaging machine packages food and non-food products in a BOPP foil. Typical packages of a flow pack are individually packaged cookies or wafers. The cookies with the coffee are also packed with a flow pack. Totalpack offers modern, user-friendly flowpack machines from an Italian manufacturer in this segment. The flow packs are equipped with servomotors and are very easy to set up on a new product. Working with a flowpack from Totalpack bvba means opting for operational reliability with a good after-sales service. You can divide the range of the flow packs into 2 large categories: flowpack machine with film roll at the bottom or flow pack machine with film roll at the top. The most used flow packer is with the film roll at the top. The flow pack machine with the bottom roll is usually used in the vegetable sector. More info about flowpacks desired? Call us without obligation.

|

|

packaging machine with shrink filmthese packing machine works with shrink film that shrinks under the influence of heat - usually these are biaxially shrinking films what means that they shrink in all directions. monoaxial shrink film shrinks only in one direction and is usually used on beam machines. In packaging machines with a shrink film, a double folded shrink film is usually used which is sealed by means of a corner sealer or L-sealer. Thereafter, the film is shrunk by heat either in a shrink dome or a shrink tunnel. With packing machines with shrink dome, the working temperature is lower than with a shrink tunnel. The shrink film used is usually different - with a packing machine with a shrink dome, a polyolefin shrink film is used that shrinks more easily at low temperature - in a shrink tunnel you can use a standard shrink film. for shrinking PE shrink film, a higher shrinkage temperature is required with cooling down after the shrink tunnel. shrink film packaging machines with a shrink tunnel can be obtained in monoblocal sealer and shrink tunnel on 1 chassis or corner sealer and shrink tunnel separately. Bundling machines almost always work with PE shrink film. this shrink film is harder to shrink but very tough after shrinking. To shrink PE shrink film you need a good shrink tunnel with cooling at the end.

|

|

wrapping film machinesthese packing machine wraps their foil around the product. These packing machines are also called ring wrappers. wrapping film is also called stretch film or stretch film. ring wrappers are usually used with long products such as shelves or profiles. more and more, however, continuous-side packaging machines are being used, which means that long products with shrink foil can also be packaged instead of wrapping film. often wrapping film machines are confused with pallet wraps.

|

|

pallet wrappersFor pallet wrappers, a wrapping foil, stretch film or stretch film is rotated around the pallet - either the pallet is turned by the film wrapper or an arm of the pallet wrapper rotates around the pallet. most pallet wrappers work with an optical eye that detects the height of the pallet. A pallet wrapper can be equipped with a pre-stretch system so that you use less foil. However, if your wrapping foil or stretch film is stretched with 200%, for example, a wrapping film of 20μ suddenly becomes 10μ more !!! With wrapping foil you also need to pay close attention to the adhesive layer and the memory. The memory of a stretch film is the extent to which a wrapping film retracts after being stretched. For example, a wrapping film that you extend to 200% with a front extension system should then return to 160% without load. When using a good quality wrapping film, your pallet is packed securely for transport.

|

|

strapping machinesstrapping machines usually bundle different collars into 1 pack by means of PP band, PP strap band or strapping band. strapping machines are also used to lay a safety belt around a suit. the tension of such a strapper can be arranged either manually or electronically. strapping machines or bundling machines with PP tape can be obtained as a table model, but also in a bow-cord machine. most strapping machines work with 9 or 12 mm PP tape - some special strappers work with 5 mm band. Portable straps are now also available that run on mains power or on batteries. such a handstrapper is very useful because it can be used virtually anywhere. strapping by hand is fairly straightforward and often offers a solution for unstable loads. strapping machines or strapping machines can also be integrated into fully automatic packaging lines or packaging streets. this way straps can also be crossed.

|

|

case sealerscase sealers at the same time stick a tape or adhesive tape at the bottom and at the top of a box. due to the adhesive tapes the boxes remain nicely closed during transport. A case sealer sometimes also only sticks tape on the bottom or top. the tape that use box sealers or sticker boxes is usually 5 cm wide - sometimes 7 cm tape is used. You can have case sealers with side conveyors or with bottom and top conveyors. you also have full-automatic box sealers that automatically adjust to the height and width of the case.

|

| COLLEGA'S : ITALDIBIPACK - FLOWPACKS - VACUMEERMACHINES - CAIMAN - -

-

- |